Corbro Equine Underlay

frequently asked questions?

01

Why is Corbro underlay different from regular foam/rubber products?

Corbro underlay is engineered for the therapeutic support and load distribution for large animals. It utilizes a chemically cross-linked polymer blend formulated to achieve optimal performance. No fillers are used in the manufacture of Corbro equine underlay.

02

Is Corbro underlay waterproof?

Yes. Corbro underlay is a closed-cell

03

What is the best way to configure sheets?

You can use Corbro underlay to cover the entire area or target specific areas as needed - choosing how to configure the sheets is entirely yours. However, we recommend a minimum width of 50mm for optimal results when working with off-cuts.

04

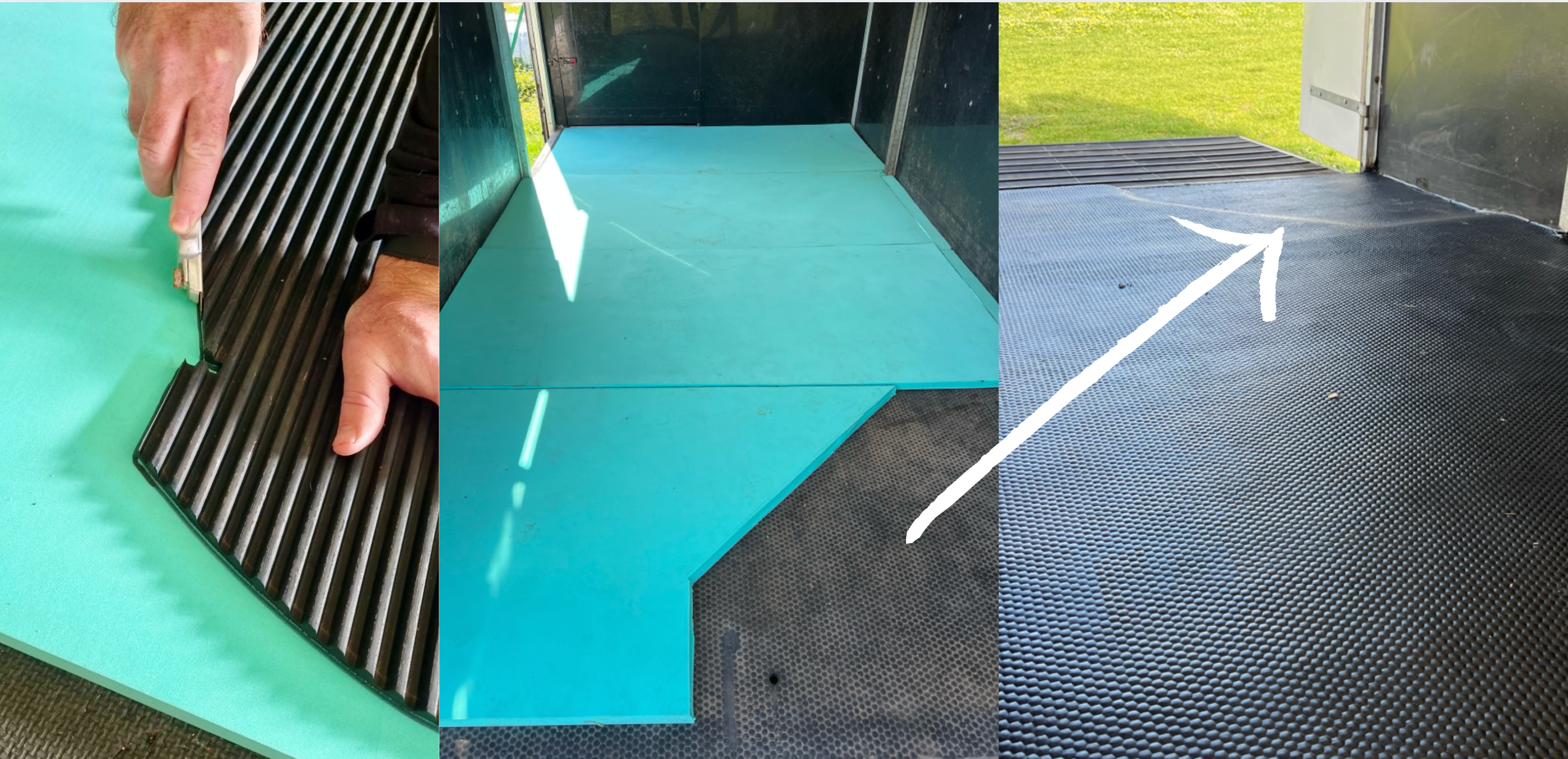

Can I put Corbro underlay on an existing rubber floor?

Yes. If the existing rubber floor is securely bonded, it can be used as the base. The existing rubber will also provide an additional sound barrier inside the transporter.

05

Should I work undercover during installation?

Yes, to prevent any expansion of the Corbro underlay sheet, always work out of direct sunlight during installation

06

Does Corbro underlay require an upper layer?

Yes, it's an underlay.

07

What rubber should I use to cover the underlay?

Most standard equine transport/flooring rubber is compatible with Corbro underlay.

08

Does Corbro underlay need to be bonded to a surface?

Yes, we recommend bonding Corbro underlay to a surface that effectively prevents foreign materials from infiltrating beneath the sheet and also ensures the sheets remain securely in place, preventing any shifting or movement."

09

Does the upper layer need to be bonded to the Corbro underlay?

Yes, we recommend bonding the upper layer to the Corbro underlay, which effectively prevents foreign materials from infiltrating beneath the upper layer, and the Corbro underlay also ensures the upper layer remains in place.

10

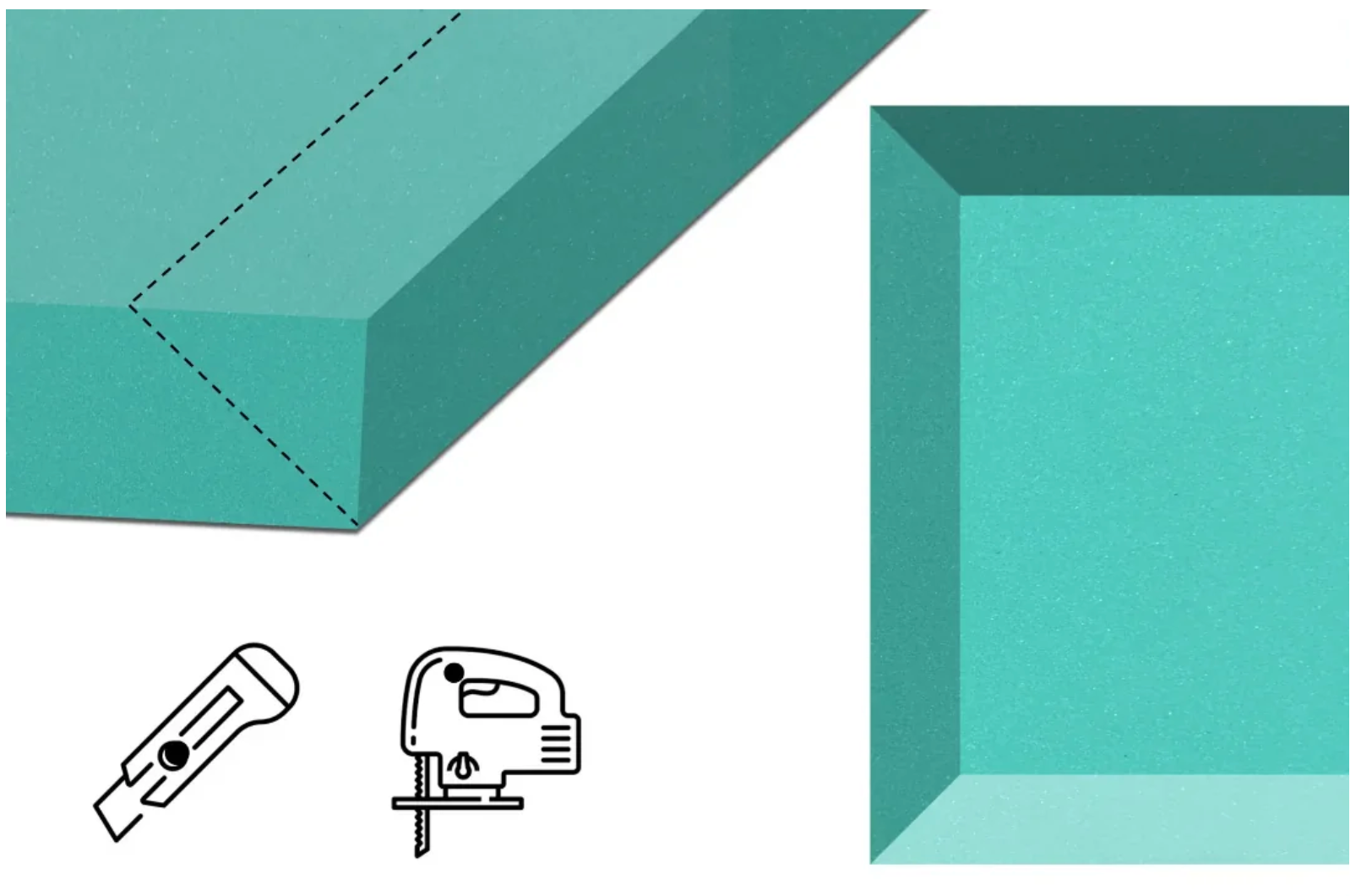

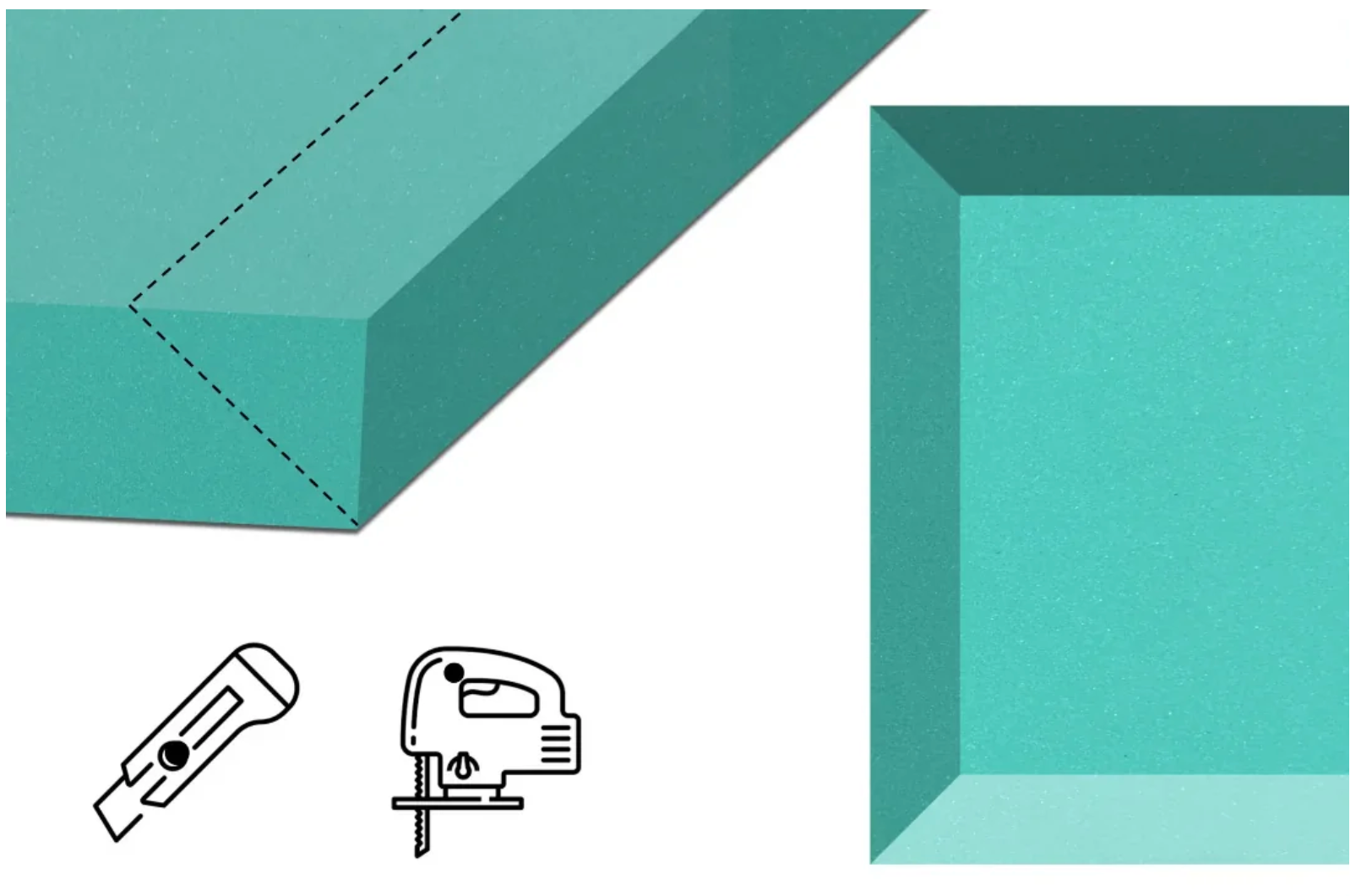

How do I cut Corbro underlay?

Corbro underlay can be cut with a utility/Stanley knife or a fine-toothed blade when using power tools.

11

What adhesive should I use with Corbro underlay?

Any rubber-compatible contact adhesive is suitable for Corbro Underlay. Consult your adhesive supplier to find the best option for your needs. Ensure it forms an industrial-strength bond and remains flexible to accommodate foam movement. Always test on a small sample before full installation.

12

Repairing & Re-bonding

Corbro underlay is a closed cell, so when re-bonding Corbro underlay or repairing sheets, it may assist in roughening the surface (underlay) with sandpaper to help with adhesion. Scoring the foam will also create adhesive hooks. Always make sure surfaces are cleaned thoroughly before re-bonding.

13

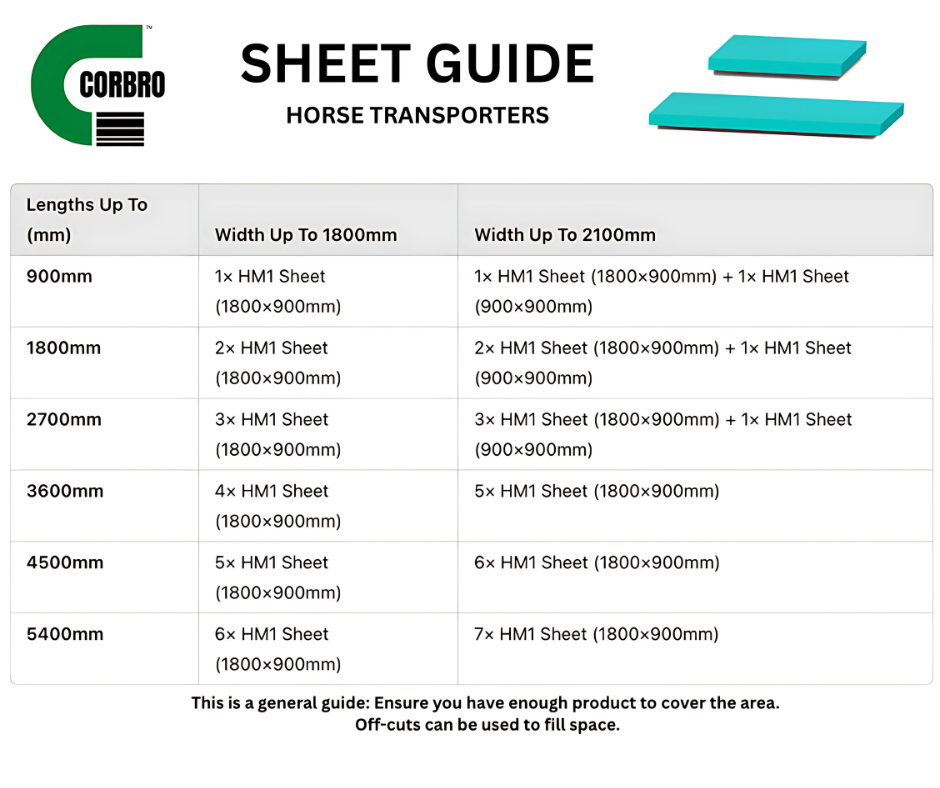

How many Corbro underlay sheets do I need for my float/truck?

14

When do I need to bevel/slope the edge of Corbro underlay

If Corbro underlay doesn't align with a surface and is left exposed, we advise cutting a tapered or sloped edge before attaching the upper layer. This precautionary step helps prevent tripping hazards and ensures a smoother surface for bonding the upper layer of Corbro underlay.

15

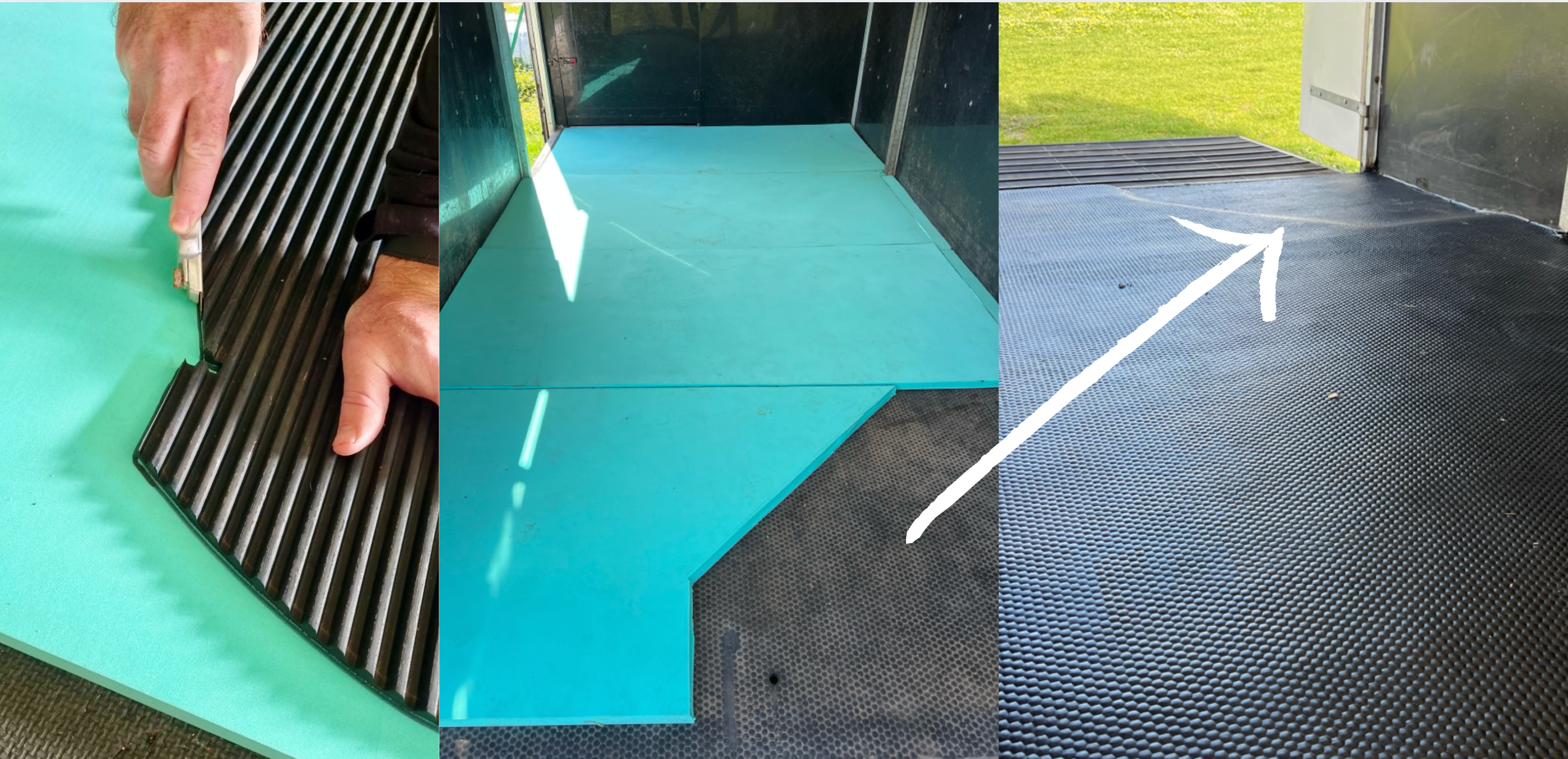

What should I do if the underlay doesn't fit beneath the tack box or a similar item?"

"If the underlay does not fit beneath the tack box, you can either raise the tack box to create more clearance or trim the underlay so it doesn't extend under the tack box (see picture)."